-

Downhole Motor

Drilling Jars

Hydraulic Oscillator

Drill Pipe & Drill Collar

PDC Bit & Tricone Bit

MWD

Fishing Tools

Drilling Tools

Equipment of Maintenance

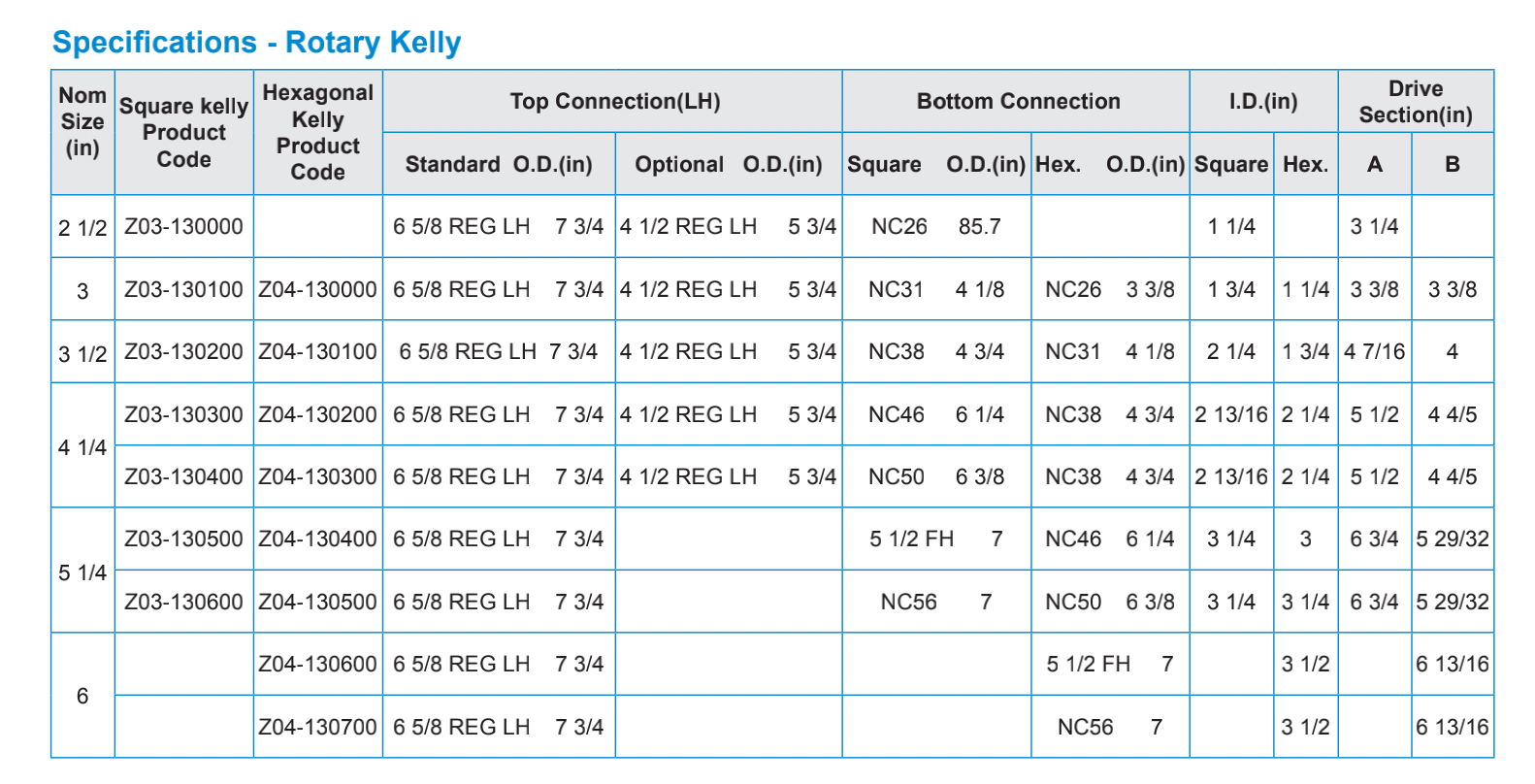

ROTARY KELLY

Straightness of the kelly is very crucial in the manufacturing process, thus straightness inspections are carried out before, during and after each machining operation. The flats are precision-milled to API specifications. All milling processes are performed on specially designed rigid Kelly mills to ensure tight tolerances and high quality drive sections. Each TIANHE Kelly is furnished with a pressed steel thread protectors.

Features and Benefits

● Manufactured from AISI 4145H-modified, fully heat-treated alloy steel with a Brinell hardness range of 285-341BHN and a minimum average Charpy impact value of 40 ft-lbs;

●Ends and drive sections, IDs and connections machined and inspected to API specifications;

● Ultrasonic inspection is performed on all sections;

● Shipped in a protective steel-cased scabbard;

When ordering please specify

● Kelly type (square or hexagonal);

● Nominal size and overall length;

● Upper and lower connections.