Sprocketed conveyor rollers are ideally suited to either pallet or heavy duty co

Sprocketed conveyor rollers are ideally suited to either pallet or heavy duty conveyors. The rollers can be supplied with single sprockets for tangential drives or double sprockets for roller to roller drives.

1. Steel sproket welded with tube, make it capable to transmit higher torque, and meet the request of transportation of heavy duty load.

2. The bearing in the end of the sproket is dismountable, not only increase load capacity, but also helpful for maintenance and replacement.

3.The covering on the outside of the sprocket, well dust proof and water splash proof in operation environment.

4. The precision ball bearing is fixed by impact in the steel bearing housing, tight and durable.Tight steel bearing housing could bear more heavier duty than polymer bearing unit.

5. Applicable temperature: -20ºC to 80ºC.

-

Nov 14 , 2022

Nov 14 , 2022API Lifting Sub, Saver Sub, Straight Sub, Reduced Section Sub, Rotary Sub

A lift Sub enables safe and efficient handling of straight OD tubulars such as drill collars, shock tools, jars, directional equipment and other tools by using the drill pipe elevators. -

Nov 10 , 2022

Nov 10 , 2022drilling jar

We designed every aspect of this double-acting hydraulic jar to withstand the rigors and long hours of challenging applications. Featuring an extra-long stroke length for exceptional impact and impulse forces during jarring operations, the Double-Acting Fully Hydraulic Drilling Jar offers infinitely variable trip loads up to the maximum rating of the tool. Only a minimal load is required in both the up and down jarring directions, which is crucial in directional, horizontal, and extended-reach wellbores. This makes the jar an ideal solution for modern drilling operations. -

Nov 08 , 2022

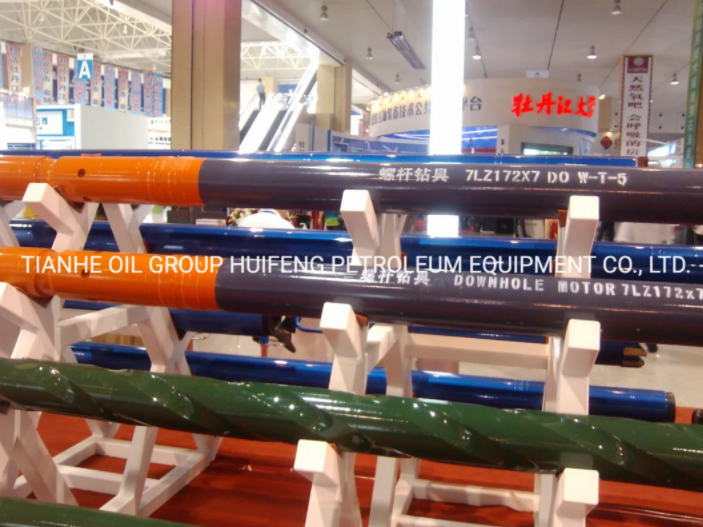

Nov 08 , 2022API Oilfield Downhole Adjustable Motor for Directional Drilling

Tianhe downhole adjustable motor offers downhole adjustment of the motor bend setting, saving time and money by eliminating trips and optimizing critical drilling parameters. Adjusting the motor bend setting while downhole improves hole quality and increases rate of penetration throughout all sections of the well. SelectShift improves rate of penetration drilling by increasing the rotary/bit revolutions per minute (rpm) in the straight position, extending well reach and reducing side-loading of the bit. This design builds off motor technology, providing industry-leading torque output capability, 100% flow to the drill bit, and reduced bit-to-bend length.