-

Downhole Motor

Drilling Jars

Hydraulic Oscillator

Drill Pipe & Drill Collar

PDC Bit & Tricone Bit

MWD

Fishing Tools

Drilling Tools

Equipment of Maintenance

SJ DOUBLE-WAY SHOCK ABSORBER

Working principle

The torsion on the drill string at the bottom of the well bore changes with respect to the type of bit structure, ground formation and bit weight. During drilling operation, the lower portion of the drill tool needs to withstand both the axial pressure and torque. This causes the drill string to undergo both torque and resonance vibration when the drilling speed reaches a certain range of values. When weight on bit exceeds its critical value (buckling load limit), the drilling operation will normally be interrupted due to stick-slip or BHA whirl (backward or forward).This is because the drilling tool will become unstable due to high transverse vibration (bending motion) and high torsional vibration (torsional motion, twist on the rod).

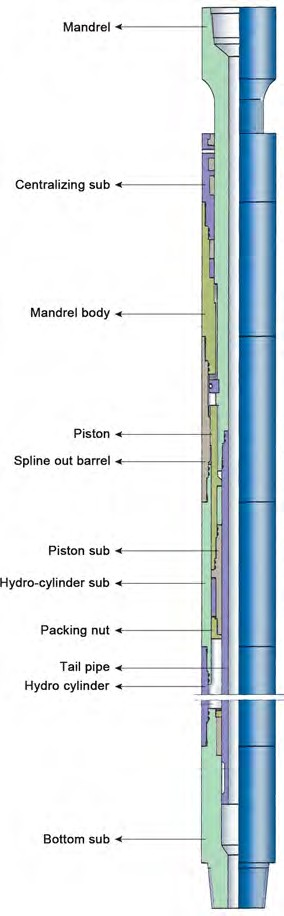

The vertical damping unit is made of mandrel, piston assembly, annular space damping unit and a fluid working chamber. In this mechanism, the compressible fluid in the working chamber acts as a spring to absorb or release the vibrational energy of the drill bit and drill string. For example, under pressure the fluid can be compressed like a deformed spring. The mandrel moves axially relative to the outer barrel when the fluid is in compression or expansion. Meanwhile the absorbed vibrational energy will be dissipated as the non-compressible fluid in the damping chamber flows through the damping space creating a great amount of heat and friction. Thus the vertical damping unit can absorb and reduce the lateral and vertical vibrational energy in the drilling tools.

The piston change-over assembly helps to maintain constant torque on the drill stem by instantly converting the torsional vibration and impact load into a vertical force component in the working chamber. The unit is composed of the spline outer barrel which is connected with the piston via a pair of rectangular spline and the piston inner surface is connected with mandrel by a pair of ladder-shaped spiral spline.

Specifications - SJ Double-Way Shock Absorber

Model | SJ46B | SJ62C | SJ64C | SJ70C | SJ80C | SJ90C | SJ94C |

Product Code | 1508000 | 1510000 | 1511000 | 1513000 | 1515000 | 1516000 | 1517000 |

O.D. (mm) | 121 | 160 | 165 | 178 | 203 | 229 | 241 |

I.D. (mm) | 38 | 47 | 47 | 57 | 64 | 71 | 71 |

Max.Stroke (mm) | 110 | 120 | 120 | 100 | 120 | 120 | 120 |

Ambient Temperature (℃ ) | -40~150 | -40~150 | -40~150 | -40~150 | -40~150 | -40~150 | -40~150 |

Max.Torque (kN.m) | 10 | 15 | 15 | 15 | 20 | 20 | 20 |

Max.Bit Weight (kN) | 200 | 340 | 340 | 400 | 480 | 540 | 540 |

Tensile Load (kN) | 1000 | 1500 | 1500 | 1500 | 1960 | 1960 | 1960 |

Pull-Down Overall Length (mm) | 4490 | 5193 | 5193 | 5620 | 5586 | 5460 | 5460 |

Connection | NC38 | NC46 | NC50 | NC50 | 6 5/8 REG | 7 5/8 REG | 7 5/8 REG |

Weight (kg) | 320 | 550 | 600 | 700 | 1000 | 1300 | 1500 |