-

Downhole Motor

Drilling Jars

Hydraulic Oscillator

Drill Pipe & Drill Collar

PDC Bit & Tricone Bit

MWD

Fishing Tools

Drilling Tools

Equipment of Maintenance

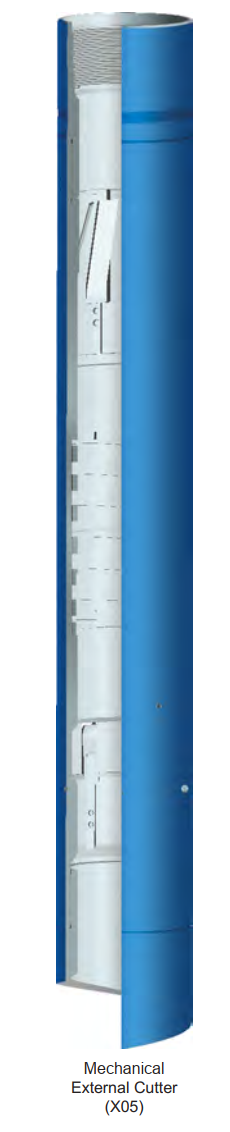

MECHANICAL EXTERNAL CUTTER

Work Principle

Connect the tool with the washover pipe and lower it to the predetermined cutting position. Lift the cutter, the circlip above the clamping sleeve inside the cutter holds the shoulder of the drill pipe (fish) sub. As we continue to lift the cutter, through the shear pin, the body pushes the feed ring upwards, compressing the spring. When the lifting force exceeds the shear pin cut-off load, the shear pin cuts off, releasing the compressed spring. The spring repels, moving the feed ring in a downward direction, guiding the knives to rotate towards the cutter center. At this instance, rotate the tool, the release of spring’s elastic potential energy gradually pushes the feed ring and knives downward until the drill pipe (fish) is cut. After cutting, the clamping sleeve clamps on to the cut tool joint, allowing it to be extracted with the cutter.

When ordering please specify:

Hole size;

Pipe O.D to be cut;

Top connection.

Specifications - Mechanical External Cutter

Model |

Product Code |

O.D. (mm) |

Dimension of cutting fish (mm) |

Max. joint O.D. of cutting fish (mm) |

Recommend connection Box |

Lifting fish capacity KN |

Shear force of shear pin KN |

Axial force of push knife KN |

WD-J102×154 |

X05-102100 |

154 |

101.6 |

121 |

5 1/2 LCSG |

20 |

10-20 |

10-30 |

WD-J140×206 |

X05-140100 |

206 |

139.7 |

165 | Users homemade |

20 |

10-20 |

10-30 |