-

Downhole Motor

Drilling Jars

Hydraulic Oscillator

Drill Pipe & Drill Collar

PDC Bit & Tricone Bit

MWD

Fishing Tools

Drilling Tools

Equipment of Maintenance

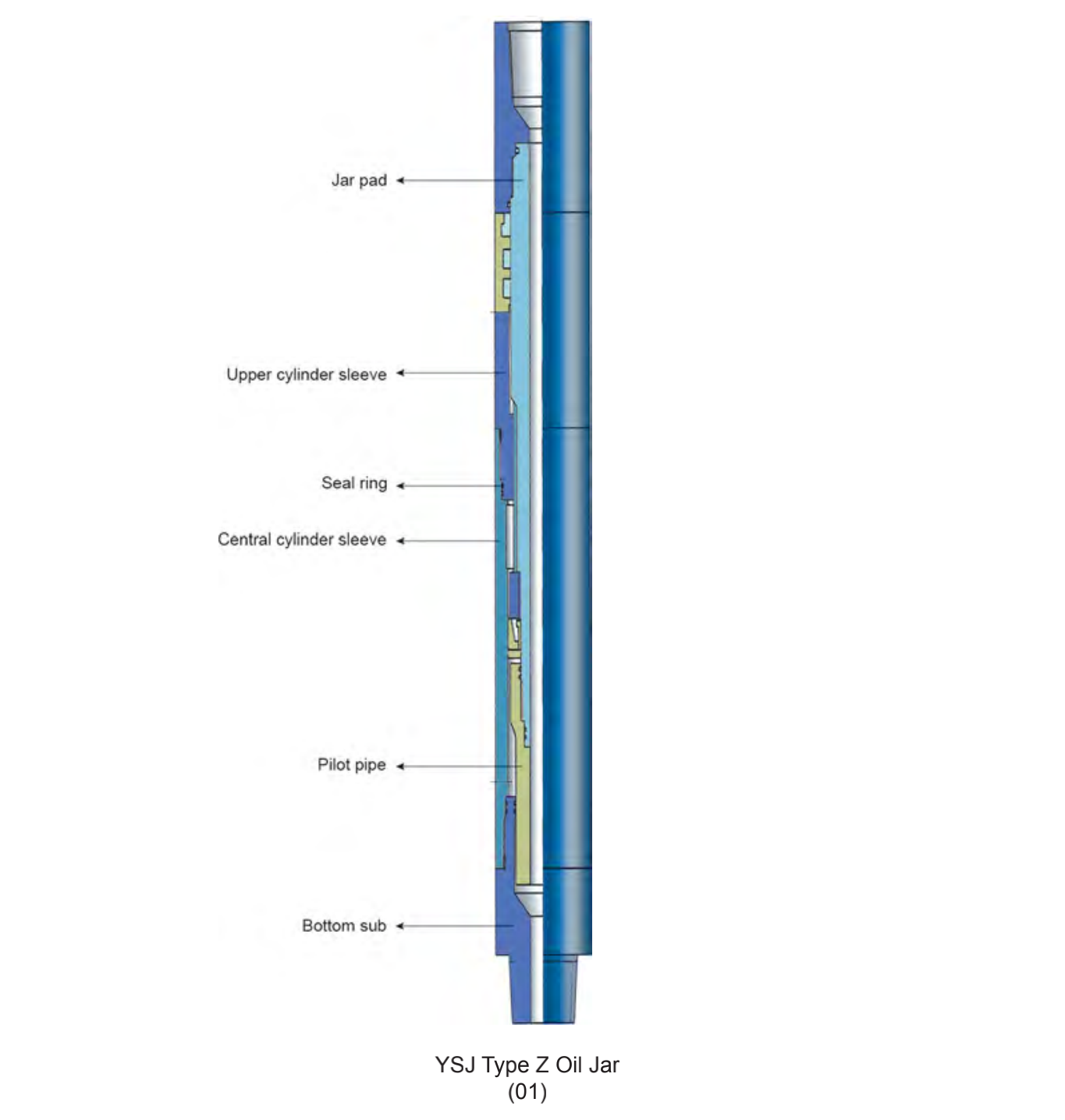

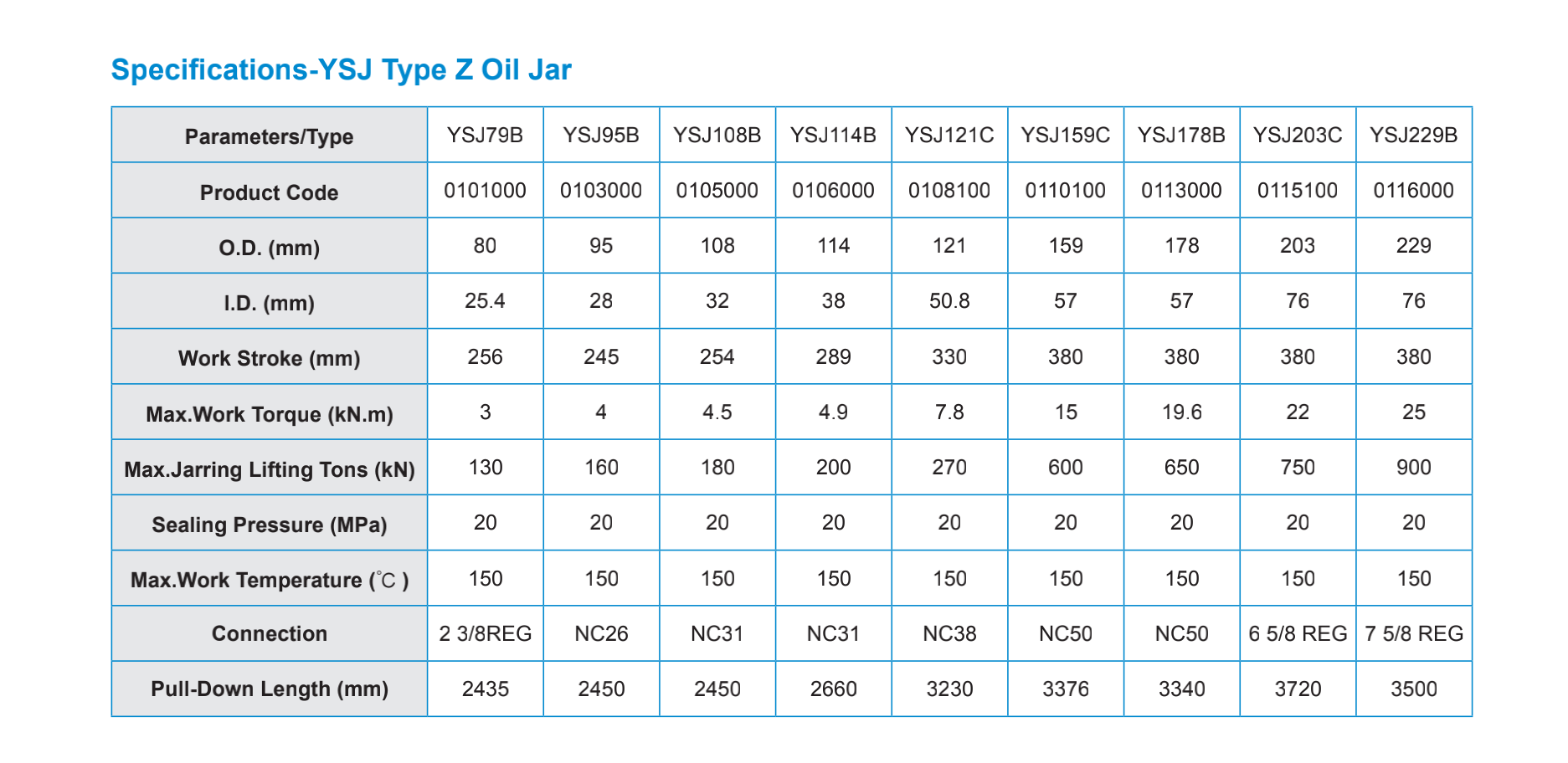

YSJ TYPE Z OIL JAR

YSJ type hydraulic jar is used to free stuck drilling tools in the well. This jar can produce large up-striking force for fishing and coring operations. Through hydraulic principle, a sudden release of the elastic potential energy that accumulates in the drill tool during the hydraulic time delay will create a large up jarring force. The key advantages of YSJ type Z oil jar is that with its simple structure. It provides strong jarring force, is easy to operate and can be easily reset to the pre-load position for consecutive jarring. For better jarring impact, YSJ type Z oil jar is recommended to be used together with the ZSJ type jar intensifier.

Working principle

As the piston in the jar slowly moves up the cylinder, the working fluid (hydraulic oil) is pressured and compressed due to its slow out flowing rate. During this hydraulic time delay, elastic potential energy starts to accumulate in the drill tool. When the piston reaches the releasing bore, the hydraulic oil gushes out releasing the pressure, giving the piston a rapid upward load and releasing the elastic potential energy in the drill tool. When the jar pad hits the bottom of the up jar cylinder it creates an impact, this strong dynamic load is then transmitted to release the stuck drill tool. An important feature of this jar is the ease of closing and resetting the tools for consecutive jarring.

PRODUCT QUOTE REQUEST

Enter your information below and we will contact you shortly