-

Downhole Motor

Drilling Jars

Hydraulic Oscillator

Drill Pipe & Drill Collar

PDC Bit & Tricone Bit

MWD

Fishing Tools

Drilling Tools

Equipment of Maintenance

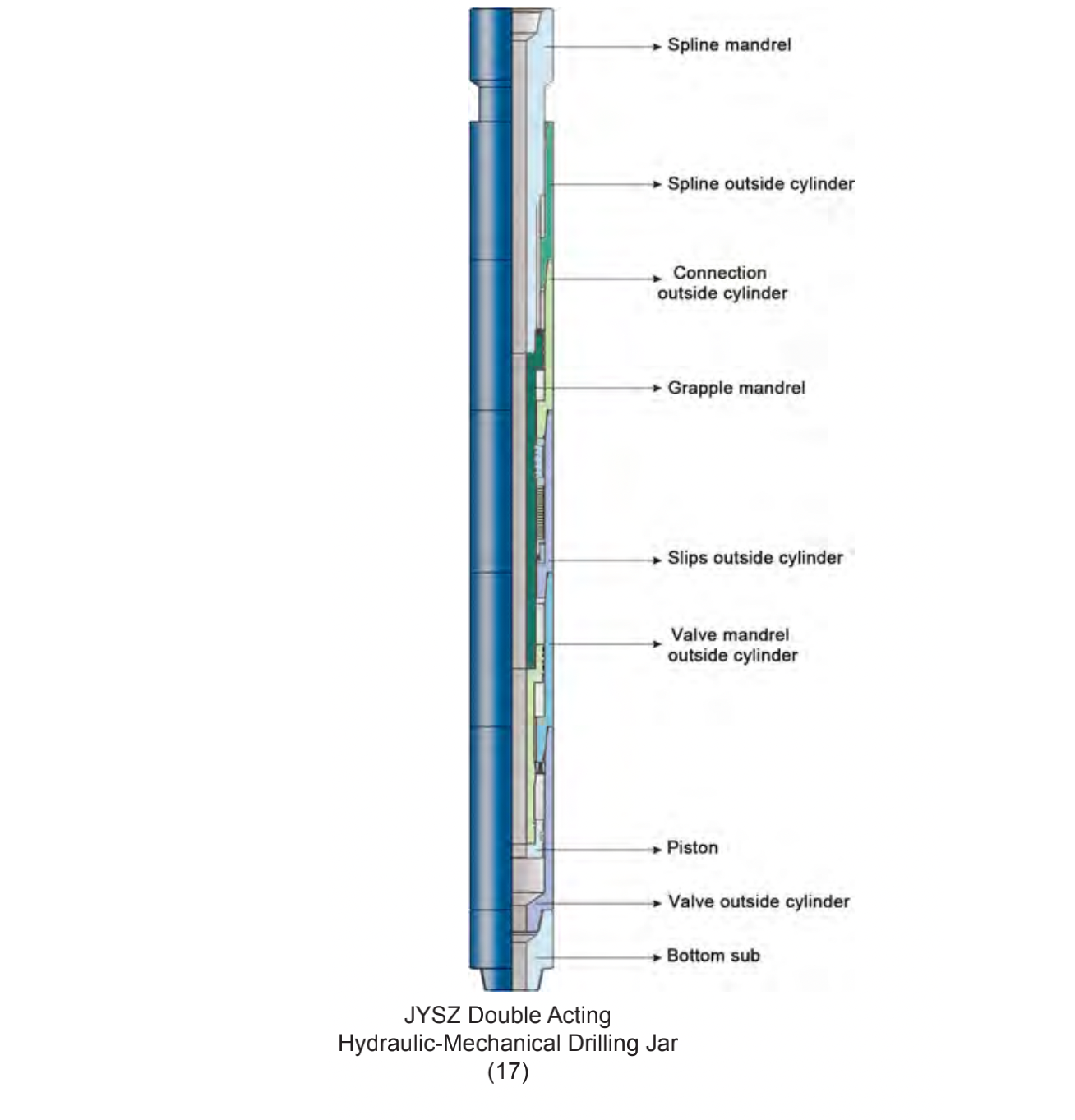

JYSZ DOUBLE ACTING HYDRAULIC-MECHANICAL DRILLING JAR

Working principle

● Up Jarring

Lower the drill stem to ensure that drilling jar is closed completely (in locking position). Up jarring is achieved by slowly increasing the lifting force on the drill stem, until there is sufficient pull force to overcome the spring resistance and initial hydraulic time delay. During the time delay, the overpull at surface can be adjusted to vary the desired impact force. When the mandrel reaches the trigger position, there is a sudden release in resistance, the elastic potential energy stored within the drill string will be transmitted to forward up jarring impact energy. After impact, apply a downward force sufficient to close jar in locking position, then repeat the jarring cycle as required.

● Down Jarring

Lift and lower the drill stem to ensure that the drilling jar is closed completely(in locking position). Down Jarring is achieved by applying sufficient downward force to compress the spring and store elastic potential energy. When the pressure of the jar is greater than the desired unlocking force, the grapple will slide away from the mandrel to release the locking, performing down jarring action. Repeat the procedures to produce continuous down jarring action.