-

Downhole Motor

Drilling Jars

Hydraulic Oscillator

Drill Pipe & Drill Collar

PDC Bit & Tricone Bit

MWD

Fishing Tools

Drilling Tools

Equipment of Maintenance

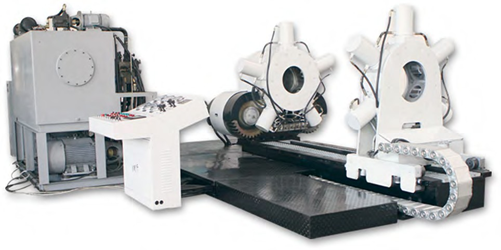

CZJQZ-II TYPE 360° ROTATION HYDRAULIC BUCKING UNIT

FOLLOWING ARE THE ADVANTAGES OF HAVING 360° CONTINUOUS ROTATIONAL HEADSTOCK:

1. Synchronized gripping force:- The headstock and tailstock each contain five radially arranged heavy duty clamping cylinders (imported). It’s designed to ensure a continuous clamping range so as to achieve synchronized gripping force on the tools and precise axial alignment of the tools.

2. Enhanced work efficiency:- The 360° continuous rotational headstock enables the make-up and break-out of tools approximately 18 times faster than normal conventional headstock design which are limited to a 40° rotation per time.

3. Reduces damage on work piece:- With the unique continuous rotational feature, only one clamping action is required to achieve a 360° locking / unlocking of the thread. This greatly reduces the number of times the work piece has to be clamped, thus reducing clamping teeth marks and damage on the surface of the work piece.

4. Precise Torque Application:- Fully imported hydraulic system ensures the accuracy of force applied on each piston cylinder, thus ensuring the precision of torque force on the tools during make-up and break-out.

Specifications - CZJQZ-II Type 360° Rotation Hydraulic Bucking Unit

Product Code |

Max. Rotary Screwing Torque |

Rotary Screwing Speed |

Dia. Range Of Work- Pieces |

Motor Power |

Rotary Screwing Motor Rated Working Pressure |

15320000 |

153KN•M |

0 - 6 r/min |

Φ73 - Φ350 mm |

64.7 KW |

18 MPa |