ABOUT US

Tianhe Chengdu company is a premium sub-brand of Tianhe Oil Group which is a world-leading company. We introduced German technology to produce high-performance drilling tools with its business covering: Explore of oil, natural gas, shale oil & gas, geothermal energy, mine exploitation and the drilling tools technology. We provide our customers with solutions, products and services. Tianhe devote us in serving global customers under a complete service chain. Until now, our business has covered over 50 countries in the world.

Drilling Tools

One stop solution for the design, manufacture, sale, rental and maintenance of drilling tools such as drill pipe, heavy weight drill pipe, drill collar, kelly, stabilizers, downhole motors, jars, absorbers, fishing tools, milling tools and valves etc.

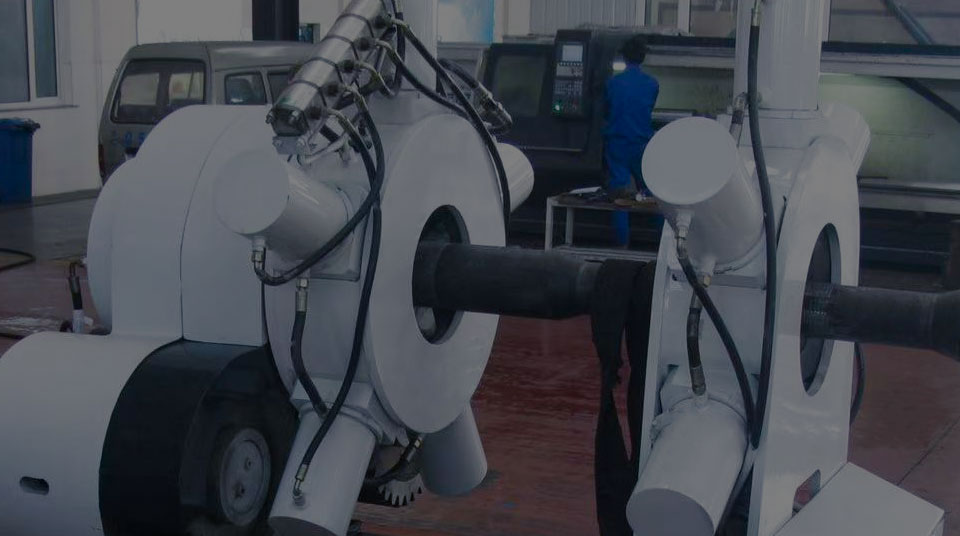

Rigs and Offshore Services

This division supports the design, manufacture, sale, rental, maintenance and other engineering services for skid mounted rigs, mobile drilling rigs, workover rigs, offshore drilling platforms and platform cranes etc.

Oilfield Engineering Services

This division provides an integrated oilfield engineering support for drilling engineering services, downhole operation services, logging services, directional drilling services, cooperative cementing services and cooperative well completion services etc.

Oilfield Exploration and Development

This scope sources, acquires and manages oilfield exploration and development projects, via wholly wned, joint ventures or profit sharing company.

Processing Trade with Provided Materials

Taking advantage of geographical logistics of Shanghai Free Trade Zone and Yangshan Port, Shanghai Tianhe undertakes processing on giving materials or samples, seeking the common development of diversified forms such as cooperation or joint venture, both domestically and internationally.

continuously strives to innovate and improve our products and expand business related to oilfield.

Over the years, Tianhe Oil Group, regarding “people-oriented, technology first, continuous improvement, casting brand” as our management guidance, continuously strives to innovate and improve our products and expand business related to oilfield.

Meanwhile, The company also increases investment in technology research and development, always takes providing the global customers with the best technical products and services as our company’s mission.

QUALITY IS LIFE

Tianhe Oil Group strongly believes and promotes Total Quality Management, implement the ISO quality management system and HSE management system and API Standard, which has been deeply implanted into every person’s thought and carried out into every aspect of work.

Our manufacturing facilities are well equipped with four automated induction heat treatment lines and dozens of other types of heat treatment ovens and well furnaces to ensure full coverage of heat treatment requirements by different products to achieve the required mechanical properties.

In order to ensure the quality consistency and interchangeability of high precision components, Tianhe has introduced WFL 5-axis Linkage Turning & Milling Machining Center from Austria, Mazak’s turn milling machining center from Japan and the Haas vertical machining center from USA. These processes are facilitated with precise quality inspection equipment such as the Brunker OES Metal Analyzers from Germany, Ultrasonic and Magnetic Powder Flaw Detector and high precision Hexagon Three Coordinate Measuring Machine and Farco Portable Three Coordinate Measuring Machine.

So far, Tianhe Oil Group has established strong business relationships with over 200 international oil & gas companies in supporting the top 50 oil producing